All vehicles need fuel and it is very important to keep track of your oil in the tank. These days there are vehicles that have a digital display but old vehicles have a fuel gauge with a needle. The mechanism of how fuel gauge works is very interesting. It is there everywhere in our cars and motorcycles and it is a very helpful device. These are pretty interesting electromechanical and digital parts used in our modern machines. The fuel gauge is one of the most important indicators in a vehicle so we want to show you how it works.

The market is now moving towards battery-powered Electric vehicles (EV). But still many vehicles operate with fossil fuels such as diesel, petrol, and gas. They all rely on indicators for various measurements. Fuel gauges operate on the electrical resistance principle with a float attached to a metallic rod as the internal ‘needle’. The basic mechanism depends on a potentiometer or variable resistor. A float is in the fuel gauge sender unit. It is connected to the resistor using an arm. The change in current is then read by the dashboard’s indicator and finally, we get the reading.

Modern vehicles also work with the same principle. However, they have a microprocessor to read the resistance or current in the circuit. They can also compensate for the shape of the tank and calculate the volume of fuel remaining very accurately. The microprocessor can also ‘dampen’ needle movement. This means that your fuel gauge doesn’t swing abruptly as you turn corners or climb hills, which sloshes the fuel in the tank, along with the float, exposing more of the rod. These things can cause errors in reading and indication.

How does Fuel Gauge work? Analog system mechanism

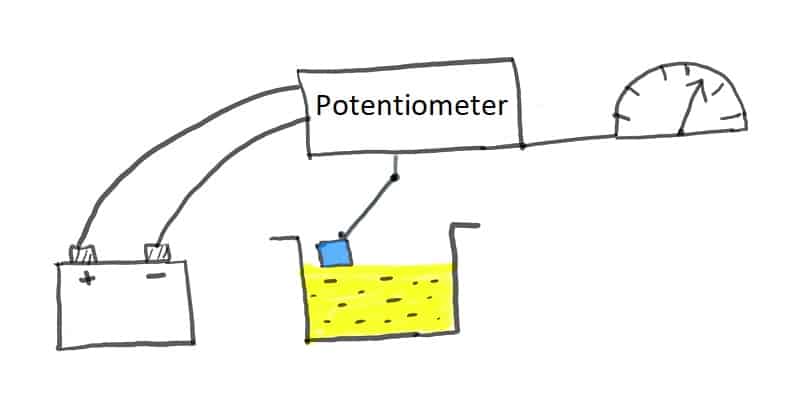

In the conventional older system, there is an oil tank, metallic rod, battery, and a variable resistor or potentiometer. We have shown this in the whole fuel gauge wiring diagram below. The major principle here is changes in resistance. Basically, there are two units in this fuel gauge system. One is the sender unit and another is the indicator unit. Sending unit is the part that checks the level of petrol or diesel and changes the resistance. The indicator unit is simply the part that is in our dashboard and shows the reading digitally or mechanically.

In a normal car or motorcycle tank, there is a float that sits at top of the fuel as it is light. The float connects to a metallic rod which connects to a variable resistor. The resistor circuit gets the power from the automobile battery. There are various regions in the resistor with different values of resistance. This is required to control the current as the position of connecting rod changes.

When the oil level drops then float also drops. The float is connected to a side or arm of a potentiometer. This changes the value of the current in the circuit. Usually, the current is lower when the level drops and when the level is up, the current is also up. It means the resistance (ohm) value is higher when the oil level drops. Thus as the vehicle moves and consumes oil, the level changes and so does resistance and current. Then the indicator in the dashboard measures the current of the circuit. The calibrated dashboard then gives us the amount of fuel in the tank. This is basically how the analog fuel gauge system works.

Modern Digital Gauge: LED, LCD, and Smart Systems

Nowadays companies are manufacturing vehicles with digital speedometers and safer fuel gauges. These are much more accurate and suffer less from breakdowns. The maintenance cost is less and life is also longer These also don’t have the chance of having broken dials. We can see people with cars that show fuel gauge reading incorrectly and the indicator is stuck in full or empty. The digital ones don’t break easily. There is higher accuracy and it is best for everyone and mainly consumers or drivers.

In newer systems, microprocessors and other electronic circuits are used for reading resistance and getting accurate data. Instead of a mechanical needle that works on the principle of electromagnetism, there is a versatile digital screen. The regular old needle system uses a basic ammeter to read the current in the system and run the calibrated dial. The digital indicators use new LCD and LED screens to display the data. In modern vehicles with smart software, a new parameter is shown which is known as DTE (Distance to Empty). The old analog gauges show the amount of oil left but the DTE system shows how much distance we can travel with the remaining fuel.

Read More: Homemade Arc welder using MOT

In the dashboard, we can also see a symbol of a pump with an arrow that indicates the direction and position of the inlet. It is called a Moylan arrow. It helps drivers to park in the correct position in the petrol pumps. This was first implemented in Ford cars. Many people still park their vehicles in the wrong direction and we can see many such funny videos on the internet.

Magneto Resistive Level Sensor

Normal gauges use float and flow of electricity in the potentiometer. This is not considered safe ideally as there can be a fire hazard. Now there is a new system of level sensors that puts the sealed system and keeps the electronics outside the tank. In the magnetoresistive fuel gauge, there is a magnet in the float arm. Its position is transmitted from the magnetic field when it moves inside the tank due to the change in level. It has very good accuracy, is very safe, and changes some mechanism of how traditional fuel gauges work. The basic principle is magnetoresistance for this type of sensor.

The automobile industry is now moving towards EV and these things will slowly fade away as we are going towards battery power. Now the industry will revolve around improving the energy density of the material and making better batteries for the vehicles. Many countries are pushing for this and we will slowly see more EVs on the roads with better technology and higher performance.